The lighting manufacturing industry is experiencing sweeping changes driven by modern software. This evolution touches every aspect of lighting products, from conception and design to production and delivery, redefining what’s possible in the sector.

The integration of innovative software tools is unlocking potential, enhancing efficiency, and creating myriad opportunities for both manufacturers and consumers.

This article will explore the multifaceted impact of software advancements on the lighting manufacturing industry, highlighting the groundbreaking changes they bring.

Computer-Aided Design (CAD)

The advent of Computer-Aided Design (CAD) has been a game-changer in the realm of lighting manufacturing.

With the aid of CAD tools, designers can prototype, visualize, and modify lighting designs with an unprecedented level of precision and detail, long before a physical product is created.

This capability not only expedites the design process but also mitigates the risk of waste, thereby promoting sustainability.

The flexibility afforded by CAD allows for the exploration of complex geometries and intricate designs, enabling manufacturers to optimize lighting parameters with ease and efficiency.

Moreover, CAD fosters innovation, empowering designers to push the boundaries of creativity and develop lighting solutions that are both aesthetically pleasing and functionally superior.

Simulation And Analysis

Simulation and analysis tools, such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), have opened new frontiers in predicting the performance of lighting products under various conditions.

These sophisticated software solutions enable manufacturers to simulate different environments and assess how lighting fixtures will respond, thereby ensuring that the final product meets the highest standards of quality and reliability.

Photometric simulations are another vital aspect, allowing the prediction of light distribution in a given space.

This analytical approach aids in product development and optimization, ensuring that lighting solutions are tailored to meet specific needs and requirements, thereby enhancing customer satisfaction and reducing energy consumption.

Internet Of Things (IoT) Integration

The fusion of lighting systems with the Internet of Things (IoT) heralds a new era of smart lighting solutions. IoT integration enables lighting systems to be embedded with sensors and connected to the internet, paving the way for remote monitoring and control.

This interconnectedness transforms ordinary lighting fixtures into intelligent assets that can adjust lighting based on real-time data, such as natural light conditions or room occupancy.

The resultant energy savings and enhanced user experiences are significant, marking a substantial leap forward in the evolution of lighting technology.

Additionally, the data collected from these smart lighting systems provides valuable insights, allowing for continuous improvement and innovation in lighting design and functionality.

Manufacturing Execution Systems (MES)

Efficiency and responsiveness are the hallmarks of Manufacturing Execution Systems (MES) in lighting manufacturing. Platforms like MRPeasy are helpful in streamlining the production process by optimizing the utilization of resources, monitoring production lines in real time, and responding promptly to any disruptions.

The seamless integration of such software solutions ensures that the manufacturing floor is a hub of productivity and efficiency, minimizing downtime and maximizing output.

This level of control and visibility across the production chain leads to consistent product quality, timely deliveries, and, ultimately, a competitive edge in the ever-evolving lighting manufacturing landscape.

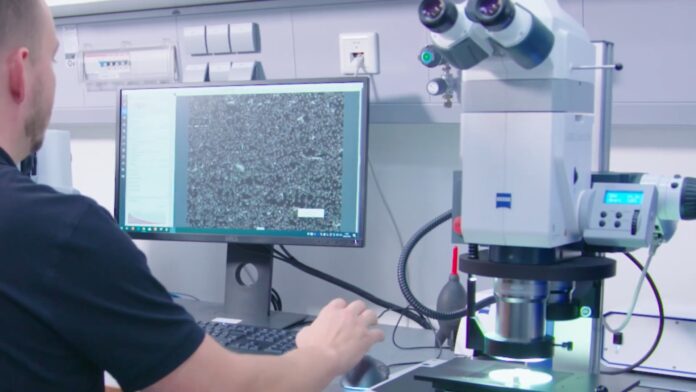

Quality Assurance

Quality assurance is a cornerstone of successful lighting manufacturing, and modern software tools are instrumental in elevating the standards in this domain.

Automation of the quality check process facilitated by advanced software ensures that each product undergoes rigorous testing and meets stringent quality criteria. This meticulous approach reduces the rejection rate and guarantees that the lighting solutions reaching the market are reliable and free from defects.

Furthermore, automated quality assurance processes lead to significant time savings, allowing manufacturers to focus on innovation and continuous improvement, thereby fostering a culture of excellence and customer satisfaction.

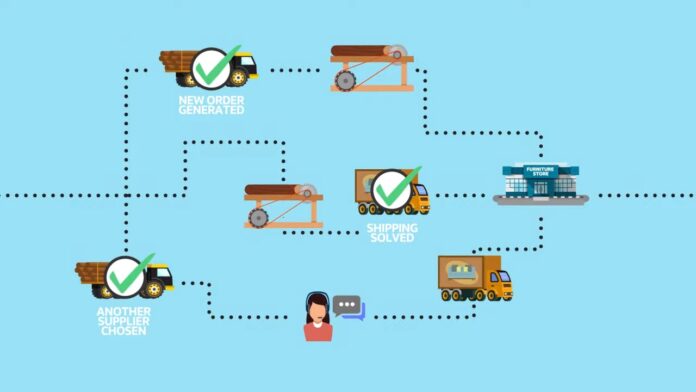

Supply Chain Management

Optimization of supply chain processes is another area where modern software is leaving a lasting imprint. Through intelligent solutions, manufacturers are achieving real-time visibility into the supply chain, ensuring the timely acquisition of raw materials and the swift distribution of finished products.

Predictive analytics embedded within these software tools are enabling companies to forecast demands accurately, thereby reducing inventory costs and preventing stockouts or overstock situations.

This real-time monitoring and predictive approach are invaluable in enhancing operational efficiency, ensuring that the right products are available at the right time, and contributing to the overall success of lighting manufacturers in a competitive marketplace.

Augmented And Virtual Reality

In the realm of visualization and customer experience, Augmented Reality (AR) and Virtual Reality (VR) are making significant strides. These technologies, backed by sophisticated software, allow manufacturers and designers to visualize lighting designs in real-world settings before they are physically produced.

For instance, architects and interior designers can employ AR to envision how a specific lighting fixture would illuminate a space, thereby making informed decisions that align with the aesthetic and functional requirements of a project.

Similarly, VR provides an immersive experience, enabling customers to explore different lighting options virtually, fostering engagement and influencing purchasing decisions.

3D Printing

The symbiotic relationship between modern software and 3D printing technology is catalyzing a new era in lighting manufacturing. This synergy enables rapid prototyping and the creation of customized and bespoke lighting designs, meeting the growing demand for personalization.

The flexibility of 3D Printing, combined with advanced software tools, allows for the exploration of unconventional geometries and structures, pushing the boundaries of what is possible in lighting design.

This innovative approach is not only fostering creativity but also reducing lead times and enabling the cost-effective production of small batches of customized lighting solutions.

Customer Customization

Empowering customers through personalization is a growing trend, and modern software is at the forefront of this movement. Online platforms are enabling customers to design and customize their lighting fixtures, creating a unique value proposition and enhancing customer engagement.

These digital interfaces offer a user-friendly experience, allowing individuals to explore various design options, materials, and finishes, resulting in a product that aligns with their preferences and needs.

This level of customization fosters a sense of ownership and connection between the consumer and the product, contributing to brand loyalty and customer satisfaction.

Eco-friendly And Sustainable Production

Sustainability and eco-conscious production are paramount in today’s lighting manufacturing industry. Modern software tools are aiding manufacturers in modeling and analyzing the environmental impact of their products.

These analyses guide the design and manufacturing processes, leading to the creation of energy-efficient and sustainable lighting solutions.

By evaluating materials, energy consumption, and waste generation, manufacturers can make informed decisions that contribute to environmental conservation. The adoption of such practices is not only fulfilling corporate social responsibility but also resonating with environmentally conscious consumers, thereby enhancing brand image and marketability.

Conclusion

The integration of modern software in lighting manufacturing is ushering in an era of innovation and sustainability.

This transformation blends design, functionality, and personalized consumer experience with technologies like IoT, AR, VR, and 3D Printing at the forefront.

Enhanced processes and quality assurance ensure the delivery of premium products, spotlighting a bright and promising future for the industry.